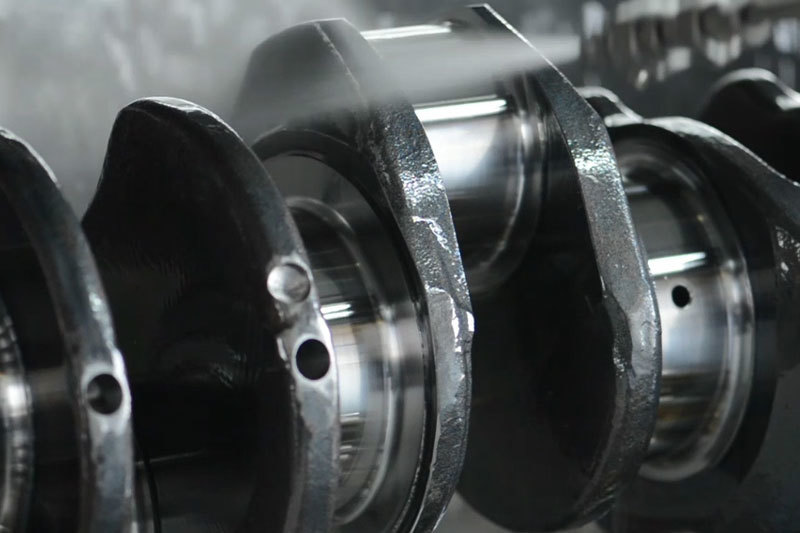

What is the structure of the crankshaft

Aug 29,2023

The crankshaft can convert the reciprocating motion of the piston into rotary motion, and convert the tangential force transmitted by the connecting rod into torque, output power externally and drive various auxiliary systems. The crankshaft is composed of the main journal, the connecting rod journal, the crank, the crankshaft balance weight and the front and rear ends of the crankshaft. The crankshaft is supported on the main bearing by the front and rear main journals. The main bearing of the multi-cylinder engine generally adopts the form of bearing pads (some also use rolling bearings). The tiles are installed in the bearing cap. The crankshaft must be axially positioned, and some use a flanged main bearing (4125A diesel engine) installed on the last bearing; some have a thrust plate on the middle main bearing. When the engine is working, the main bearing and the main bearing seat are under great force. Therefore, when installing the main bearing cover, the main bearing bolts must be tightened with the specified torque, and locked with locking pieces.

Both the main journal and the connecting rod journal are lubricated by pressure oil, and the oil is sent from the main oil passage on the body to the surface of the main journal, and then sent to the surface of the connecting rod journal through the inclined oil passage between the main journal and the connecting rod journal. . There is a cylindrical cavity in the connecting rod journal, and the two sides are blocked with oil plugs, and the oil can be centrifugally purified during operation. After a certain period of operation, the cavity will deposit a large amount of impurities, which must be cleaned regularly.

The crank is the connecting part of the main journal and the connecting rod journal. The crankshaft balance block is set at the lower end to balance the centrifugal force generated when the connecting rod journal etc. rotate, reduce the vibration of the diesel engine and prolong the life of the bearing.

The front end of the crankshaft is equipped with a crankshaft timing gear, which is used to drive other gears in the timing gear chamber to rotate, so as to complete the functions of gas distribution, speed regulation, and balance. The front end of the crankshaft of the multi-cylinder machine is also equipped with a V-belt pulley and a starting claw that drive the water pump and the fan. The rear end of the crankshaft is connected with the flywheel. Oil retaining pans are arranged at the front and rear ends of the crankshaft, and oil seals are installed at the timing gear chamber cover at the front end and the outside of the main bearing cap at the rear end to prevent oil leakage in the crankcase. In order to ensure that it is coaxial with the crankshaft, the oil seal seat or the oil return baffle and the body have positioning pins for positioning. Some sealing devices at the rear end of the crankshaft use oil return threads, such as the 4125A diesel engine.

PREVIOUS:

Contact Us

E-mail :

crqp@hbcrqp.com

Phone/WhatsApp:

+86-18333932227

+86-18333959666

Address:

West of Ergeying Village, Youfang Town, Qinghe County, Xingtai City, Hebei Province, China