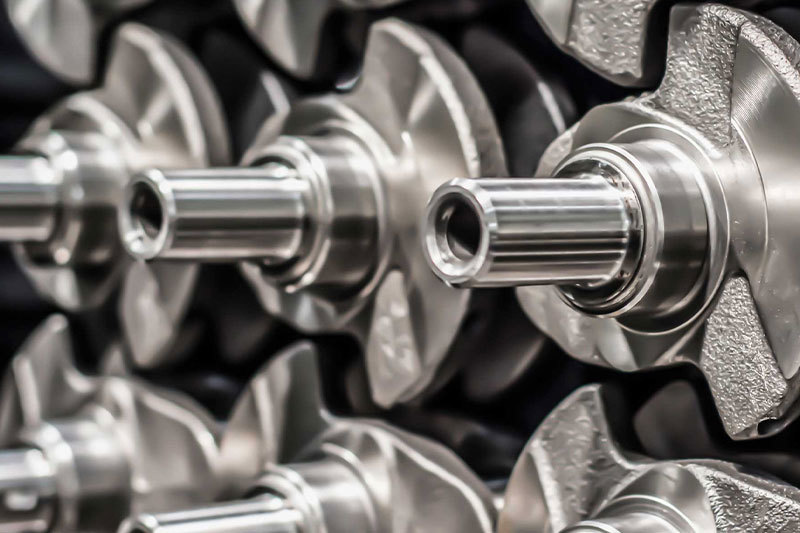

Basic knowledge of crankshaft

Aug 29,2023

How the crankshaft works:

The crankshaft is one of the most typical and important parts in the engine. Its function is to convert the gas pressure transmitted by the piston connecting rod into torque, output work as power, drive other working mechanisms, and drive the auxiliary equipment of the internal combustion engine to work.

The crankshaft is one of the key components of the car engine, and its performance directly affects the life of the car. When the crankshaft is working, it is subjected to heavy load and constantly changing bending moment and torque. The common failure forms are bending fatigue fracture and journal wear, that is, bending fatigue damage and torsional fatigue damage. The probability of the former is greater than that of the latter. Bending fatigue cracks first develop in the connecting rod journal (crank pin) or main journal fillet, and then develop towards the crank arm. Torsional fatigue cracks are generated in poorly processed oil holes or fillets, and then develop in the direction of the axis. Metal fatigue failure is the result of variable stress that changes periodically with time. Statistical analysis of crankshaft damage shows that about 80% is caused by bending fatigue.

The main reasons for crankshaft fracture:

(1) Due to poor road conditions and severe overloading of the vehicle, the engine often runs within the critical speed of torsional vibration, and the shock absorber fails, which will also cause the crankshaft to break due to torsional vibration fatigue damage.

(2) Long-term use of engine oil deteriorates; severe overloading and overhanging cause long-term overloading of the engine and cause tile burning accidents. The crankshaft was severely worn due to engine burnout.

(3) After the engine is repaired, the vehicle has not passed the running-in period, that is, it is overloaded and overslung, and the engine runs overloaded for a long time, so that the crankshaft load exceeds the allowable limit.

(4) Overlay welding is used in the repair of the crankshaft, which destroys the dynamic balance of the crankshaft, and the balance check is not done, and the unbalance exceeds the standard, which causes a large vibration of the engine and leads to the fracture of the crankshaft.

Crankshaft maintenance precautions:

(1) During the crankshaft repair process, the crankshaft should be carefully inspected for cracks, bending, twisting and other defects, as well as the wear of the main bearing bush and the connecting rod bearing bush, to ensure that the main journal and the main bearing bush, the connecting rod journal and the connecting rod bearing bush The clearance between them is within the allowable range.

(2) Crankshaft cracks mostly occur at the transition fillet between the crank arm and the journal, and at the oil hole in the journal.

(3) When repairing and reassembling the crankshaft, the flywheel should be kept in balance.

(4) After major accidents such as tile burning and cylinder smashing have occurred in the internal combustion engine, a comprehensive overhaul of the crankshaft should be carried out.

PREVIOUS:

Contact Us

E-mail :

crqp@hbcrqp.com

Phone/WhatsApp:

+86-18333932227

+86-18333959666

Address:

West of Ergeying Village, Youfang Town, Qinghe County, Xingtai City, Hebei Province, China